Flexographic Printing Machines | for High Quality Prints

Updated: December 5, 2024

104

Imagine creating colorful designs on things like cereal boxes juice cartons and gift wraps this is where flexographic printing machines come in. These machines are like magical tools that help print beautiful images and words on materials such as paper plastic and even metal. They are super important in making the packaging and labels we see every day.

Flexographic printing or flexo for short works a bit like using stamps. The machine has special plates made from rubber or plastic, which are shaped like the designs you want to print. These plates pick up ink from rollers and then press it onto the surface of the material. It fast clean and can handle big printing jobs making it perfect for factories that need to print hundreds or thousands of items.

One cool thing about these machines is that they can print on almost anything flat or even bumpy surfaces. That why they are used to make labels for bottles wrappers for candies and even patterns on fabric. And guess what. Flexographic machines are also eco friendly. They use water based inks which are better for the environment compared to other printing methods.

Flexographic printing machines are like superheroes in the world of printing. They help businesses make products look great while also being fast reliable and good for the planet.

What is a Flexographic Printing Machine?

A flexographic printing machine is like a giant stamp making tool that helps print colorful designs pictures and words on materials like paper plastic or cardboard. Think of it as a fast and efficient way to decorate packaging labels and other products you see in stores.

These machines use flexible plates made of rubber or plastic. Each plate has a design on it and it rolls ink onto the surface similar to how you would use a stamp to decorate paper. What makes it special is its ability to work on all sorts of materials including soft and hard surfaces.

Flexographic printing machines are great for creating large amounts of high quality printed items quickly and with fewer mistakes making them super important for industries like food packaging and labels.

You May Also Visit It!

TPE Printing | 3D Printing with Flexibility & Strength

What Is a Screen Printing Machine | A Guide to Bold Prints

Screen Printing Ink | Transform Ideas into Art with Vibrant

Top Screen Printing Roller Frames | Achieve Perfect Prints

Key Components of Flexographic Printing Machines

Flexographic printing machines are made up of several important parts that work together to create high quality prints.

Here are the key components in simple terms:

1. Printing Plates

These are like big rubber stamps that hold the image or text you want to print. The plates are flexible, so they can be easily attached to the machine. Each color in a design needs a separate plate.

2. Anilox Rollers

Think of these like special paintbrushes. These rollers control how much ink goes onto the printing plate. They have tiny cells that hold the ink so the print comes out clear and sharp.

3. Ink Delivery System

This system controls how the ink moves to the printing plate. The ink needs to be spread evenly so the print looks nice. The anilox roller helps with this by putting just the right amount of ink on the plate.

4. Substrate Feeding System

The substrate is the material being printed on like paper plastic or cardboard. This system helps move the material through the machine without any mistakes so the ink is printed in the right place.

5. Drying or Curing System

After the ink is printed on the substrate it needs to dry or set. This system uses hot air UV light or other methods to make the ink dry quickly and stick well to the material.

These parts work together to make sure that printing is fast accurate and high quality. They help the machine print on many different types of materials like labels packaging and more.

Types of Flexographic Printing Machines

Flexographic printing machines come in different types, each designed to meet specific needs in the printing process.

Here a simple explanation of the different types:

1. Inline Flexographic Printing Machines

These machines print on a roll of material and process everything in one go. This includes printing drying and sometimes cutting. They are great for producing packaging materials like labels and bags quickly and efficiently.

2. Stack Flexographic Printing Machines

In this machine the printing units are stacked one on top of the other. It a good choice for printing on larger surfaces and works well for businesses that need to print high quality labels and packaging.

3. Central Impression Flexographic Printing Machines

These machines have a large cylinder in the middle that holds the printed material while the printing plates surround it. This design helps produce clear consistent prints across large rolls of material making it ideal for printing on plastic foil and other flexible materials.

4. Letterpress Flexographic Printing Machines

These machines are similar to traditional printing presses but use flexible plates instead of metal ones. They are perfect for smaller print runs and are often used for tasks like printing business cards or invitations.

5. Wide Web Flexographic Printing Machines

These machines are designed for printing on very large rolls of material such as those used in large scale packaging. They are often used by companies that need to print in bulk such as for large cardboard boxes.

Each type of machine is suited for different jobs based on the material you are printing on the speed you need and the quality of the print. Flexographic printing machines are versatile which is why they are widely used in industries like packaging labeling and textiles.

Applications of Flexographic Printing Machines

Flexographic printing machines are used in many industries to create different products that we see and use every day.

Here are some of the most common uses:

1. Packaging

Flexographic printing is widely used to print on packaging materials like boxes bags and wrappers. This includes products like cereal boxes snack bags and even food containers. It helps make these packages colorful and easy to read.

2. Labels

Flexographic printing is also perfect for printing labels on bottles cans and other products. For example it used for printing the labels on your favorite juice bottles or shampoo containers.

3. Newspapers and Magazines

Some newspapers and magazines use flexographic printing because it can print quickly and in high volume. This helps them produce large numbers of copies at a low cost.

4. Plastic Films

Flexo is great for printing on flexible plastic films which are used for things like food packaging and protective coverings for products. It makes the print stick well and look sharp on these smooth surfaces.

5. Paper Products

Flexographic printers can print on many types of paper from tissues to napkins to wrapping paper. The prints are clear and durable which is important for paper products that are handled a lot.

Flexographic printing is used everywhere to make sure products look good are easy to recognize and are safely packed for use.

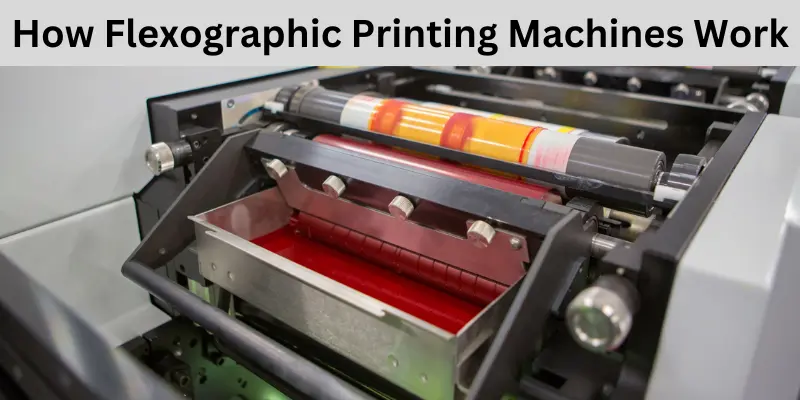

How Flexographic Printing Machines Work

Flexographic printing machines are like giant stampers that can print on all sorts of materials like paper plastic and even fabric.

Here how they work in simple steps:

1. Making the Plates

The first step is creating special plates that carry the image or design you want to print. These plates are made from flexible materials like rubber so they can bend and wrap around rollers.

2. Inking the Plates

Ink is spread onto the plates using rollers. These rollers are designed to carry just the right amount of ink so the image comes out clear and sharp.

3. Printing the Design

The inked plate presses onto the material (like paper or plastic) transferring the image. The pressure is carefully controlled to make sure the design looks good and does not get blurry.

4. Drying the Ink

After the image is printed the ink needs to dry or harden. Some machines use heat or special lights to speed up this process.

5. Rolling Up the Printed Material

Finally the printed material is rolled up ready to be used for packaging labels or anything else.

This printing process is super fast it perfect for making lots of items quickly and with high quality.

Impacts of Flexographic Printing Machines

Flexographic printing machines are super important in today world especially for making things like packaging labels and even food wrappers. These machines have made a big difference in the printing industry.

Here are some of the ways they have impacted businesses and everyday life:

1. Faster Printing

Flexographic printing machines can produce large quantities of items in a short amount of time allowing factories to manufacture more products in less time. For instance millions of labels or boxes can be printed daily.

2. Superior Quality

These machines deliver high definition prints with great clarity ensuring that products like shampoo bottle labels or toy boxes have bright sharp designs.

3. Versatile Materials

One of the standout features of flexographic printers is their ability to print on a wide range of materials including paper plastic metal and fabric. This versatility makes them ideal for various applications from food packaging to clothing.

4. Cost and Time Efficiency

Flexographic printing reduces time spent on setup and design changes resulting in cost savings. This efficiency allows businesses to print more while minimizing waste making it perfect for large scale production.

5. Eco Friendly

Compared to traditional printing methods flexographic printing is more environmentally friendly. It uses water based or soy based inks which are safer for the planet helping companies reduce pollution and waste.

Flexographic printing machines have revolutionized the printing process making it faster more efficient and environmentally friendly. They enable businesses to save money produce high quality products and contribute to a greener planet.

Effects of Flexographic Printing Machines

Flexographic printing machines have significantly transformed the production of labels boxes and various types of packaging. These machines are versatile capable of printing on a wide range of materials including paper plastic and even metal.

Here how they make a difference:

1. Faster Printing

Flexographic printing is incredibly efficient allowing for the production of large quantities huge advantage for businesses needing to quickly produce items like boxes for new products.

2. Cost Effective Production

Thanks to their fast operation flexographic printers help businesses save on both time and materials. The efficiency of the printing process means that less ink and material are used which reduces waste and cuts costs.

3. Superior Quality

Flexographic printing delivers high quality sharp and clear images. It a detailed image on a food package or a label on a bottle the print quality is consistently excellent.

4. Versatility with Materials

Flexographic printing stands out because it can print on almost any surface plastic paper fabric and more. This flexibility is especially beneficial for companies producing a wide range of packaging for different products.

5. Environmentally Friendly

Modern flexographic printers are designed to be more eco friendly using water based inks and sustainable materials. This reduces pollution and makes the printing process more environmentally responsible.

Flexographic printing machines not only make printing faster cheaper and higher quality but they also contribute positively to the environment.

You May Also Visit It!

Top Tube Printing Machine | Quality & Efficiency

UV Curable Ink Printer | Vibrant Colors with a Touch of Magic

Soft Touch Printing | Enhance Tactile Customer Experience

Screen Printing Materials | for Stunning Vibrant Results

Advantages of Flexographic Printing Machines

Flexographic printing machines are a great tool for printing on many different materials like paper plastic and even metal. They have several benefits that make them popular for printing jobs especially in packaging and labels.

| Advantages of Flexographic Printing Machines |

|---|

|

Disadvantages of Flexographic Printing Machines

Flexographic printing machines offer many benefits but they also come with some disadvantages that may make them less suitable for certain businesses. Here are the main drawbacks explained simply.

| Disadvantages of Flexographic Printing Machines |

|---|

|

FAQs About Flexographic Printing Machines

Flexographic printing machines are used to print on different materials like plastic paper and metal. They are fast and efficient making them perfect for producing high quality labels packaging, and more. These machines use flexible plates and special rollers to apply ink creating clear and detailed prints even on curved surfaces.

What is a flexographic printing machine?

A flexographic printing machine is a type of printing press that uses flexible rubber or plastic plates to print on different materials like paper, plastic, and even metal. It commonly used for printing labels packaging and other products.

How does flexographic printing work?

In flexographic printing a plate with your design is placed on the printing machine. The plate is inked and then it presses the design onto a material (like paper or The process is fast, and the prints are clear and colorful.

What kinds of materials can be printed with flexographic printing?

Flexographic printing can be used on many types of materials such as paper plastic films fabric and even metal. This is why it great for packaging labels and wrapping.

What are the benefits of using flexographic printing machines?

Flexographic printing machines are fast reliable, and can print on different materials. They are perfect for big jobs like printing thousands of labels or boxes. They also use less ink than other printing methods which can save money.

What are the challenges of flexographic printing?

One challenge is that setting up the machine can take some time especially when switching between different jobs. The machines also require regular maintenance to keep them running smoothly.

Why is flexographic printing popular for packaging?

Flexographic printing is used a lot for packaging because it works well on a variety of materials like plastic paper and even cardboard. It also produces bright sharp images making products look appealing to customers.

How long do flexographic printing machines last?

With proper care and maintenance flexographic printing machines can last many years. Regular cleaning and checking the parts are important to keep them working well.

Are flexographic printing machines expensive?

Yes flexographic printing machines can be expensive, but they are worth it for businesses that need to print large quantities of products. The speed and quality they offer can help companies save money in the long run.

Can flexographic printing be used for small projects?

Flexographic printing is best for large projects like mass-producing labels and packaging. For small custom jobs, other printing methods like digital printing might be a better choice.

What are the new innovations in flexographic printing?

Recent improvements in flexographic printing machines include better ink systems automation to reduce human work and even eco friendly options that use less energy and water.

Conclusion

Flexographic printing machines are amazing tools that help create high-quality prints on many things, like packaging and labels. They use flexible plates to transfer ink to different materials making it perfect for printing on things like plastic, paper and even fabrics. These machines are fast cost effective and can handle large jobs with ease.

One of the best parts is that they can print on many different materials making them super flexible for many businesses. Flexographic printing is also great because it uses less ink and has fewer mistakes helping companies save money. As technology improves these machines will become even better at making prints faster and cleaner.

Flexographic printing machines are a great investment for any business that needs fast high quality prints on different materials. They make packaging, labeling and printing easier and more affordable.

You May Also Visit It!

Technical Screen Printing Tech | The Key to Success

Laser Printing Stages | History, Types, Uses and Benefits

Oki Laser Printer | Features, Application and Benefits

Akiles Printing | History, Uses, Types and Applications

Digital Web Print | Perfect Prints Every Single Time

Please Write Your Comments